Ultimate Guide : Sidemount Cylinder Trim

This is my comprehensive guide to the good, the bad and the ugly of sidemount cylinder trim. The aim of this article is to illustrate and explain the common errors that cause less than ideal sidemount trim and frustrate sidemount divers.

Use the illustrations and diagrams in this article in comparison with photos and video of yourself in the water – to help understand and diagnose where you might be able to improve your sidemount configuration.

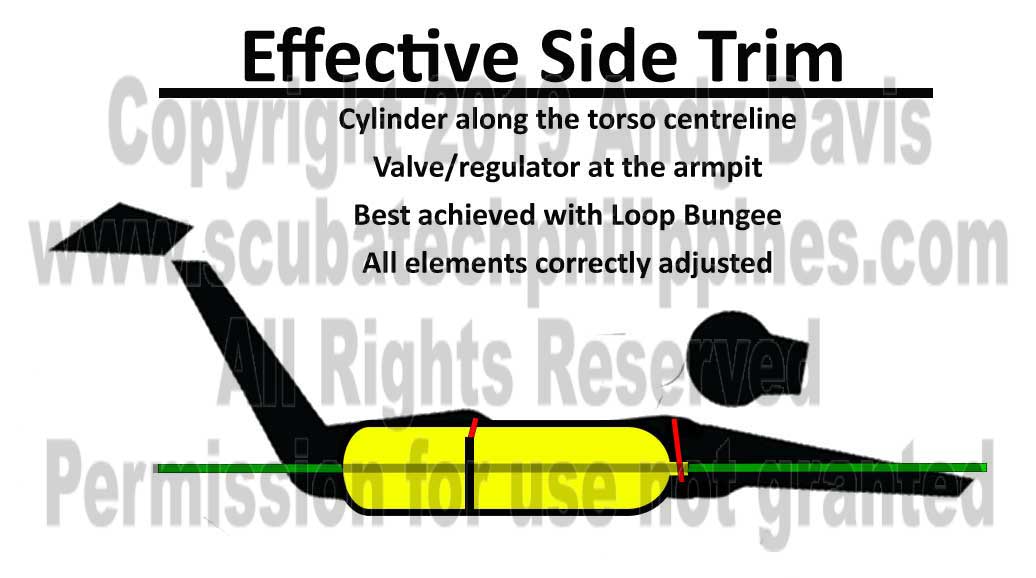

Effective Sidemount Trim

First of all, lets look at what represents the ideal sidemount cylinder trim:

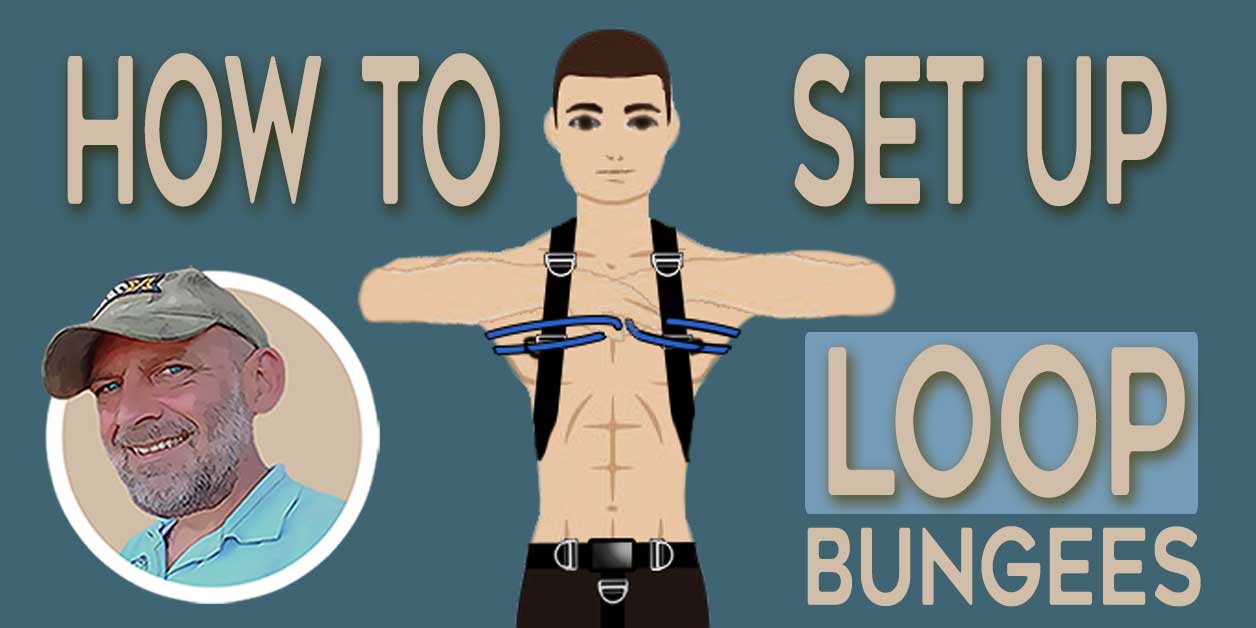

From the above illustration, we can see that the cylinder is actually AT THE SIDE of the diver. The valves/regulators are just below the armpit and the cylinder runs precisely along the side-centreline of the diver’s torso.

The key attribute is that the mid-line of the cylinder runs along the mid-line of the diver’s torso.

I’ve always found that Loop Bungees are the most effective in promoting a truly effective sidemount cylinder trim. They cause a tank rotation into the side of the diver and, when correctly configured, enable the cylinders to be kept in perfect alignment at all times.

Loop bungees are especially popular with divers using aluminum cylinders, but I know of many sidemount divers who’ve used them very successfully with steel cylinders also.

The photo above demonstrates a very ideal sidemount trim. Both the diver AND his cylinders are perfectly horizontal and this will promote the highest degree of streamlining throughout the dive.

This photo (above) also demonstrates a perfect alignment between diver and cylinders.

Using loop bungee, the cylinders will remain in this position relative to the diver – even when the diver maneuvers around, or leaves the horizontal trim position.

This photo shows very good alignment between cylinders and diver – except that the diver has raised his head, and consequently his upper torso, for easier forwards visibility.

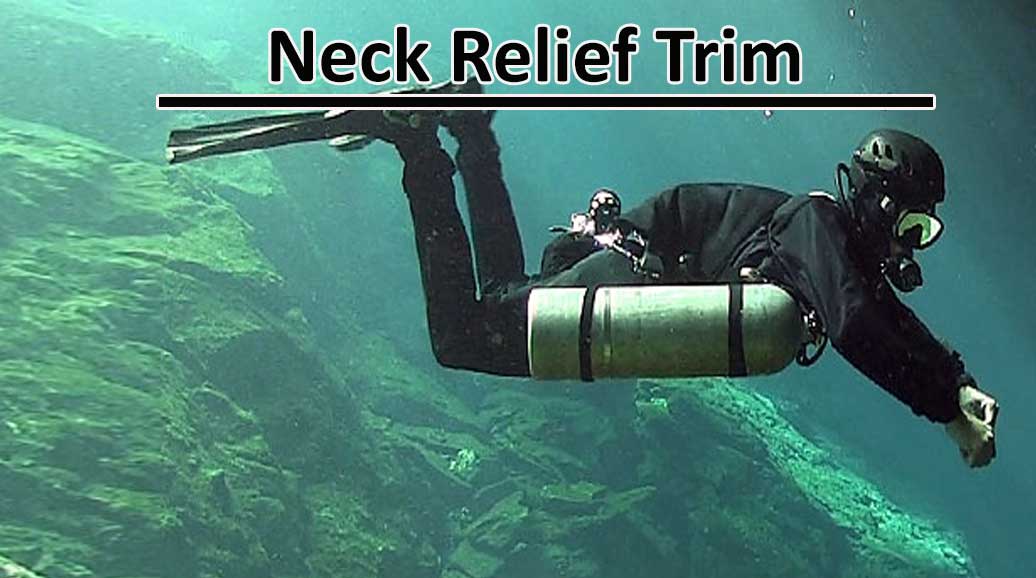

Some divers experience difficulty (read; neck ache!) when maintaining very flat, horizontal, body trim. Not everyone enjoys a high range of neck flexibility. Divers can solve this by posturing upwards with their upper torso to relieve the strain on their necks.

It’s less streamlined outright… but comfort is definitely an important criteria.

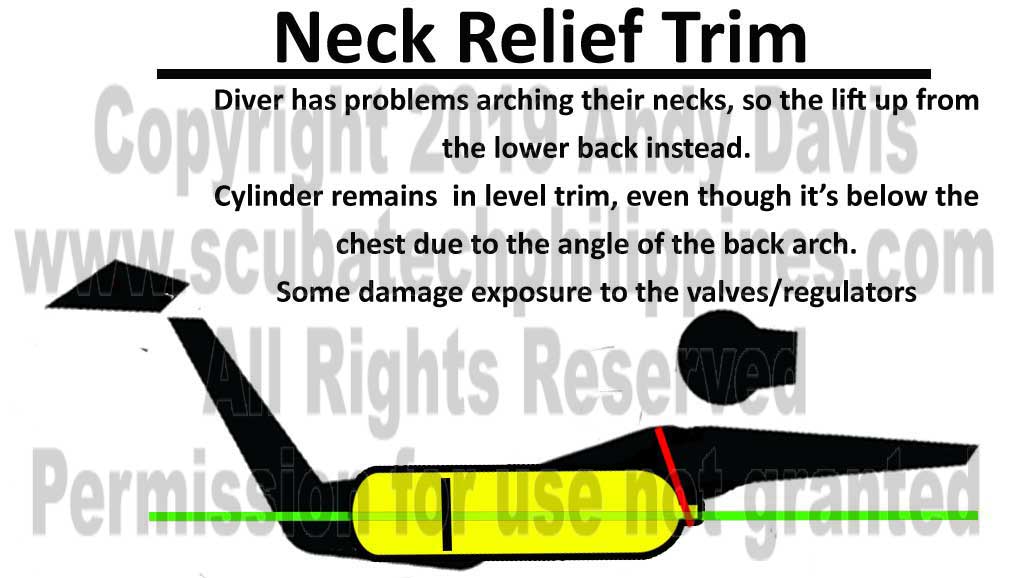

Neck Relief Trim

Exaggerating the back arch can relieve strain on the neck.

This raises the upper torso whilst the cylinder remains horizontal. I call this ‘neck relief trim’.

In the picture above we can see a very minor elevation of the upper torso.

Nonetheless, the cylinder remains flat with respect to the hips and knees.

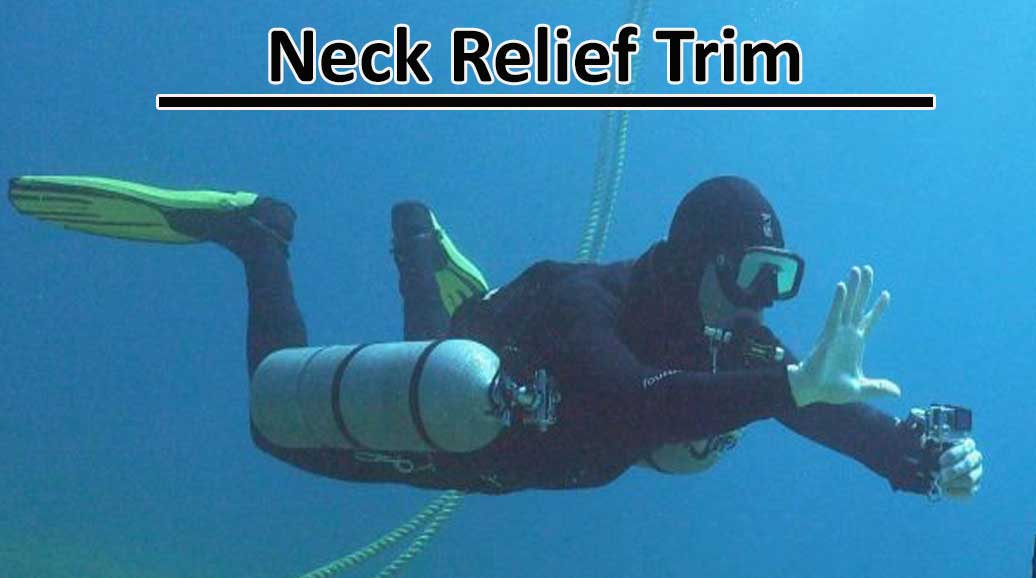

Another illustration of ‘neck relief trim’, showing flat cylinders and proper body posture.

And again, you can see very nicely trimmed cylinders, but a slight exaggeration in the arch of the spine enables easy forwards vision and situational awareness.

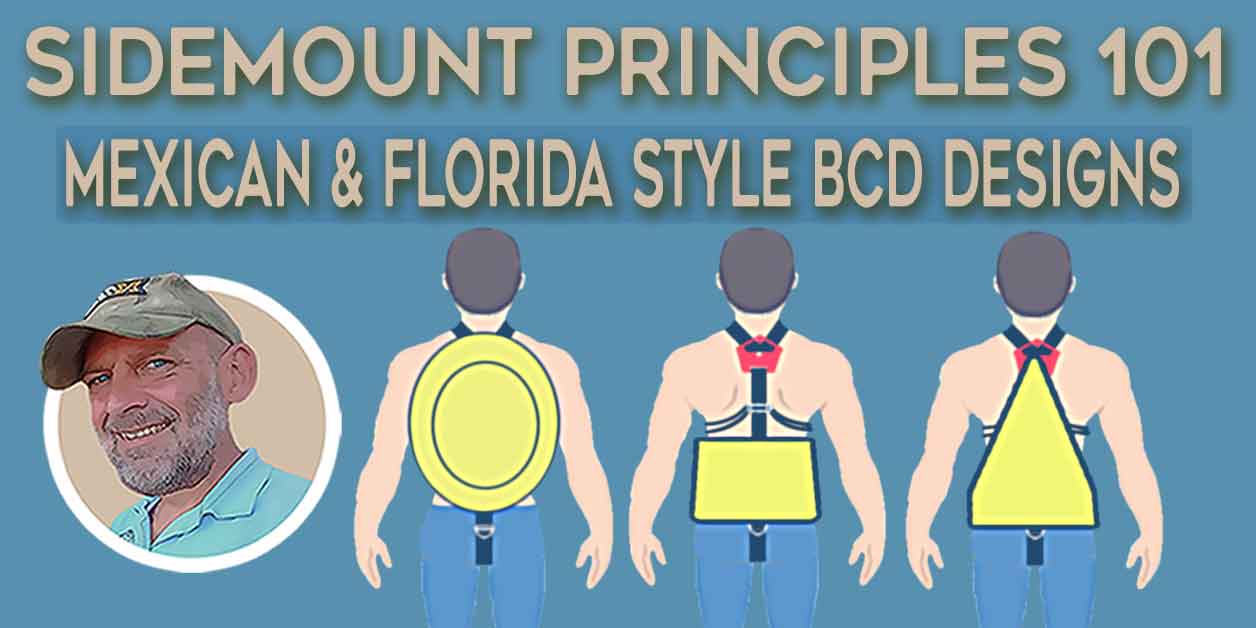

Buy my ‘Sidemount: Principles For Success’ ebook now!

My comprehensive guide to sidemount configuration and development as a diver.

178 Pages. PDF format. Only $25

Fully Illustrated!

Chapters include:

- Sidemount history, design styles, and cylinder principles

- Harness and bungee setup and sizing

- Configuring deco/stage cylinders

- Diagnosing cylinder trim problems

- Regulators and hardware

- Training and skillset development

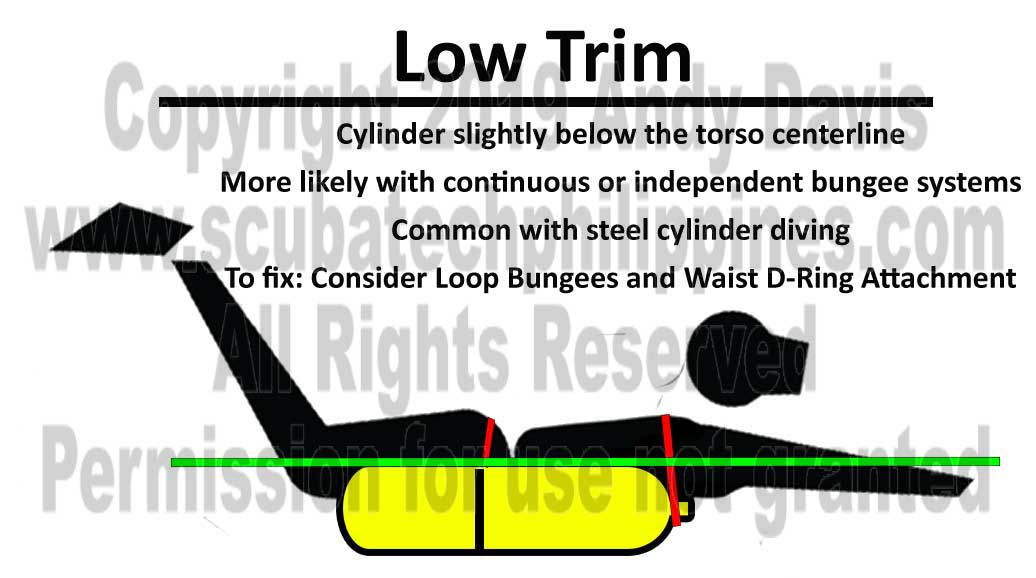

Low Cylinder Trim

Low trim isn’t necessarily ‘bad’ trim. The cylinders are slightly lower – at maybe 45 degrees from the torso centreline. It results from certain bungee configurations that aren’t able to torque the cylinders as snug into the side of the torso. You will see slightly ‘lower trim’ from many divers using continuous or independent style bungee systems.

This differs slightly from what I’d describe as ‘ideal’ trim, in that the top of the cylinder runs along the mid-line of the diver’s torso.

Above is an obvious example of low cylinder trim. The cylinder is almost just below the diver. The valves are far below the armpit; but this is also due to some ‘neck relief’ back arching. The diver is using steel cylinders, which do often tend to ride a little lower – especially when attached via a butt-plate and independent or ring type bungees.

When the bungees ARE keeping the valves up snug in the armpits, but the lower attachment is either too long, or attached to the wrong position (i.e. when using waist D-rings), then we have what I call a ‘butt heavy’ trim.

For a good insight into configuring steel cylinders for effective trim, do read Steve Lewis’ article: GETTING SIDEMOUNT TANKS TO BEHAVE THEMSELVES AND SIT WHERE THEY SHOULD

Butt Heavy Cylinder Trim

The most common cause of ‘butt heavy trim’ seems to be when aluminium cylinder divers mistakenly attach their cylinders to the front waist D-ring too quickly. If the tanks are still negative when the attachment is moved forwards, then the tank will obviously hang low at the rear.

Occasionally it can occur by having the read D-ring (the first attachment point) set too far forwards on the waist belt.

With steel cylinders, the same effect can occur if the lower bolt-snap and/or leash is sized too long. It’s easy to fix by shortening the bolt-snap leash and/or buying a shorter length boltsnap.

The example above clearly shows how the rear of the tanks drop down below the body of the diver. He’s diving aluminium cylinders, but has added lead weights as a short-cut to learning proper techniques for diving aluminium.

Those lead weights mean the cylinders won’t ever get buoyant (as steel cylinders don’t). In this case, he’s simply set the attachment points far too low, or rigged the leashes/bolt-snaps far too long.

In some scenarios where you are close to the seabed, or cave floor, this can mean damage to the environment below you. At the very least, it will cause the cylinders to act like pendulums and reduce your sensation of stability.

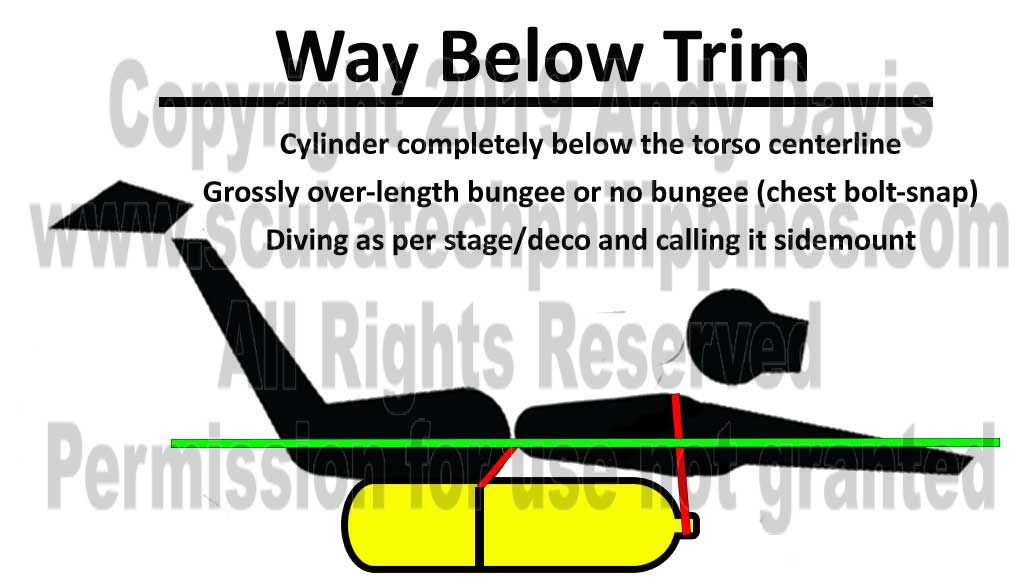

When a diver has BOTH the top and bottom attachment points configures too long, or too low, then it causes what I call ‘Way Below Trim’. That’s because the tanks are way, way below the diver. This is sidemount diving… not belly mount..

Way Below Cylinder Trim

When the entire tank hangs too far below the diver it destroys any semblance of stability, as the cylinders are free to swing around below the body.

In minor cases, it may be due to simply having the bungees and lower attachments configured too long. It’s a simple adjustment to fix.

The photo above illustrates cylinders that are just a bit too low to be classed as properly in trim. They are basically just below the body.

We can see that the lower attachment point is far too long and the bottom of the cylinder is clearly below the level of the thigh and knee. The bungees also are either too long, or too flexible, and the tank valve is hanging 6-8″ below the armpit.

The above photo is hilarious. It’s more ‘frontmount’ than sidemount. In this instance the diver hasn’t used bungees at all, but rather has clipped his cylinders onto the chest D-rings using bolt-snaps.

This is the approach that technical divers might use with stage/deco cylinders, but it certainly isn’t applicable to sidemounting primary cylinders.

You can see how the diver has lost much of the freedom-of-movement with their arms; and they would struggle to access any equipment on their chest or front waist. It’d be tricky finding the LPI quickly underneath those tanks.

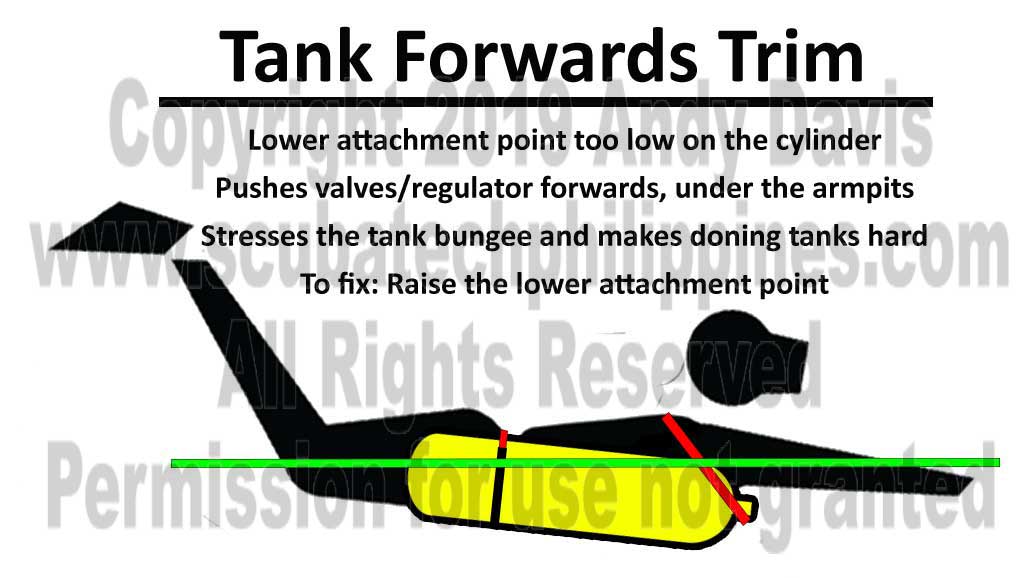

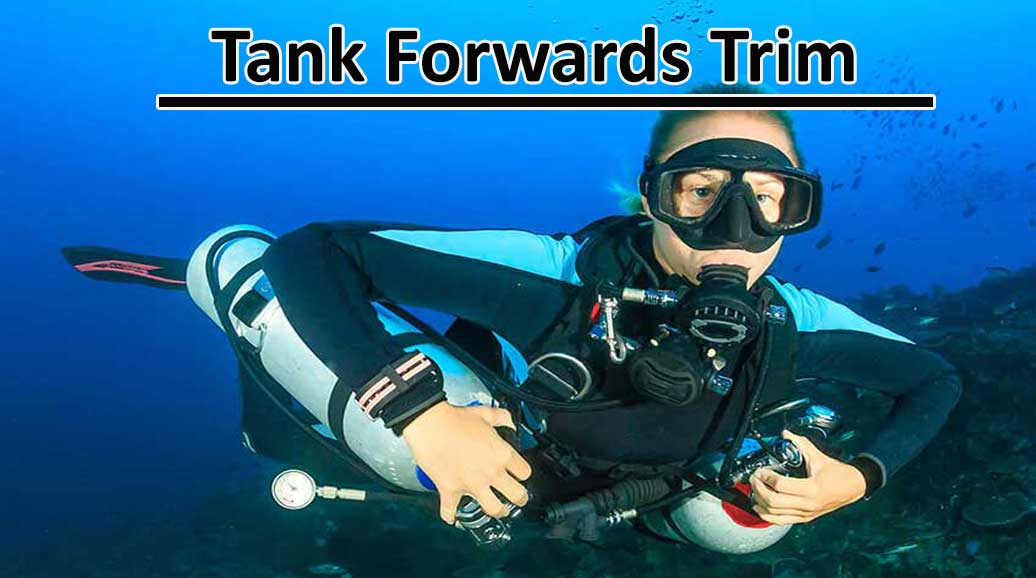

Another error that deteriorates arm mobility and the ability to access equipment as easily is the ‘tank forwards’ trim.

Tank Forwards Cylinder Trim

The ‘tank forwards trim’ occurs most often when the diver has configured their cylinder band too low. The effect of this is to push the entire cylinder forwards relative to their torso. Sidemount cylinder trim won’t be possible.

Learn how to configure your cylinder bands in this article: How to find the Optimal Height for Sidemount Cylinder Bands.

The cylinder bands should provide a ‘base’ from which the tanks cannot move forwards when under tension from the bungees.

Properly configured Loop Bungees don’t tend to pull the tanks forwards, but continuous and independent bungees tend to be setup higher on the shoulders-chest – and this will pull the tanks forwards of the armpit if not restrained by the lower attachment.

The example above shows well trimmed ‘low’ cylinders, but the valves are slightly forwards of the armpits. This is a usual result when using continuous bungee systems. The downside is that it impairs arm mobility.

The example above shows how the cylinder bands are set very low. The result of this is that the valves/regulators are pushed forwards of the armpits and forced downwards. As the valves are pushed down, then naturally the tail of the tank will pivot upwards.

The diver has to endure a cluttered front torso and, evidently, feels it necessary to physically restrain his wayward tanks using his hands for support.

The above photo is a very extreme example of ‘tank forwards trim’. In this case the root cause is a grossly incorrect fitted BCD – you can see the waistbelt is right up under the ribcage, rather than low down on the hips where it should be.

Obviously, this makes the cylinder attachment point much, much too high. The diver can’t raise the cylinder band any higher, or it’d be above the fulcrum/balance-point of the tank and trim would be utterly impossible.

The cylinder is pushing a clear foot beyond the armpit of the diver. It’s forced down by the armpit and that tilts the bottom of the cylinder high above the diver. This would not feel very nice to dive.

You can imagine if the waistbelt were 12″ lower on the torso, then the whole cylinder would be pulled backwards by a corresponding distance… and the problem would largely be solved.

If you find yourself in this sort of ludicrous pose during a sidemount dive, then you may well be suffering from ‘tank forwards trim’;

Of course, having the cylinders too far forwards isn’t the only issue that can cause the valves to drop below the body.

Another major culprit is having your bungees too long, or too weak.

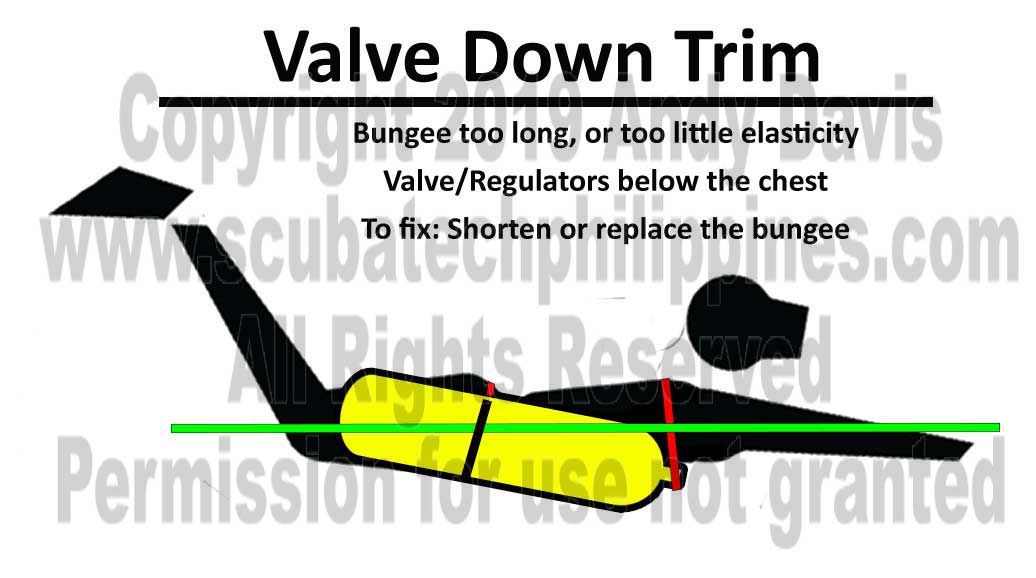

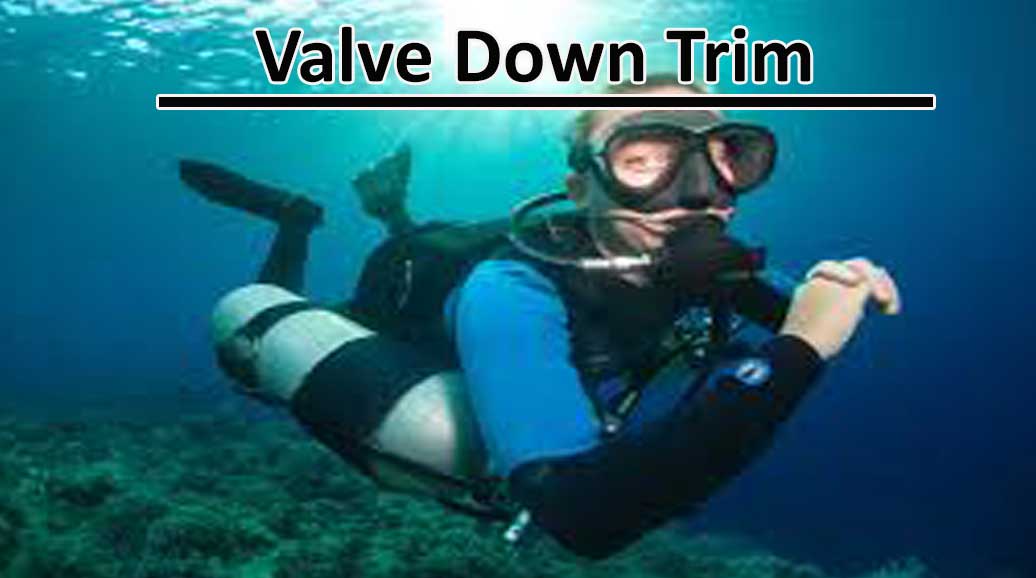

Valve Down Cylinder Trim

Novice sidemount divers often start out with their bungees too long. This is invariably because they struggle with the actions required to get the bungee around the cylinder valve. Sorry to say folks, but that’s a SKILL problem, not an equipment problem.

Over the years, I’ve noticed that newbie (and some not so new!) sidemount divers have a tendency to want to watch what they’re doing when they put bungees around their valves. This means they hold the cylinders forwards of their body as they attempt to wrap the bungee.

Holding the cylinder forwards, whilst it give a clear view of what you’re doing, also means that you need to stretch the bungee a much greater distance.

Hey presto… the bungee is now “too short” and the diver feels tempted to lengthen it. The result is a slack setup where the tank valve hangs much too low below the armpit. And consequently, the bottom of the tank will pivot upwards too.

When I teach students, I stress the need to keep the valve snug back under the armpit when securing the bungee. Of course, that means you cannot see what you are doing. It’s a hand skill, not an eye skill.

Take enough time to practice any you’ll develop an efficient muscle memory for getting the bungee on.. and you won’t have to compromise with bungee length, or turn your fingers to rubber fighting the elasticity of a grossly over-stretched bungee.

The example above shows how the valve is well below the chest of the diver. In this case it’s about 50/50 between ‘tank forwards trim’ (look at where his tank bands are) and ‘valve down trim’.

It could go in either category, but I put it as an example of ‘valve down trim’ because the bungees are still evidently quite long. Otherwise the sidemount cylinder trim would be much tighter up against his armpits.

The above photo really illustrates some very LONG bungee indeed. There’s clear daylight between the valve and the diver’s chest. This bungee should be shortened by at least 12-18″ (under tension).

His lower cylinder attachment is also too far forwards; I could have used this an example of ‘way below trim’… except his body posture is weak at the hips and his legs are dropping down. That somewhat conceals how low his cylinder actually is at the rear.

The sidemount diver, above, has gone to great lengths to add weight to his aluminium cylinders in a failed attempt to stop the tanks rising behind him.

Adding weights won’t ever work when the valves of the cylinders are still allowed to drop down by over-length bungee – and in this instance, another dose of ‘tank forwards trim’ also.

This is a classic example of a diver having incorrectly been taught, or learnt, how to dive as for steel cylinders and then tried to make the same configuration and approach work for aluminium tanks.

Adding lead weights to the tanks is a bit of desperate ‘faux-alchemy’ intended to make aluminium behave like steel tanks when it comes to buoyancy characteristics.

The problem, however, isn’t the tank buoyancy behaviour, but rather that the lower attachment point is a buttplate, not suitable for aluminium tanks, and that the bungees are way too long.

So, we can see that having some attention-to-detail with bungee length and the correct physical procedures for donning the bungee is vital for preventing ‘valve down trim’. We can also see that the lower attachment point also plays a critical role in keeping the bottom of the tank low and trimmed against the thighs.

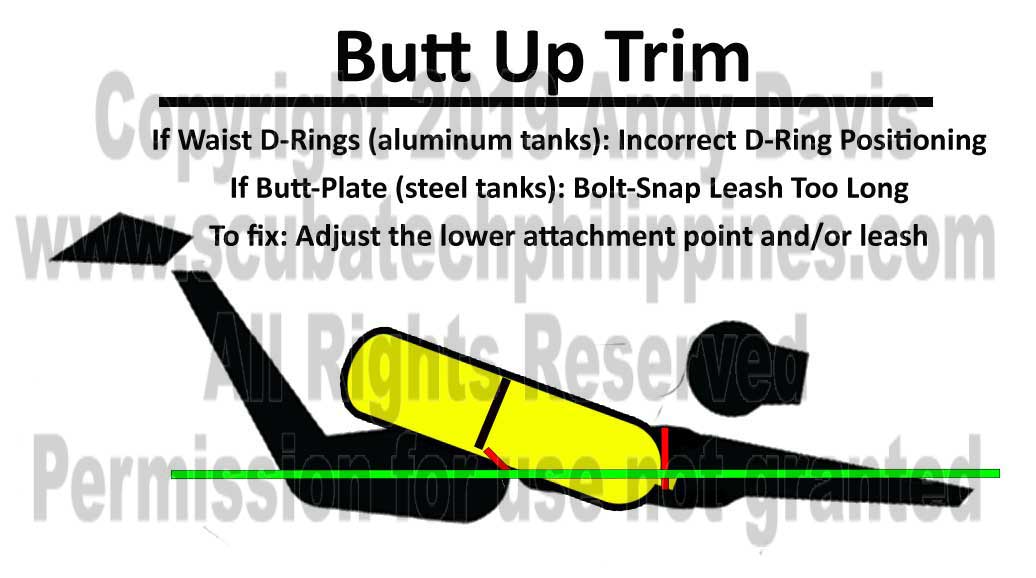

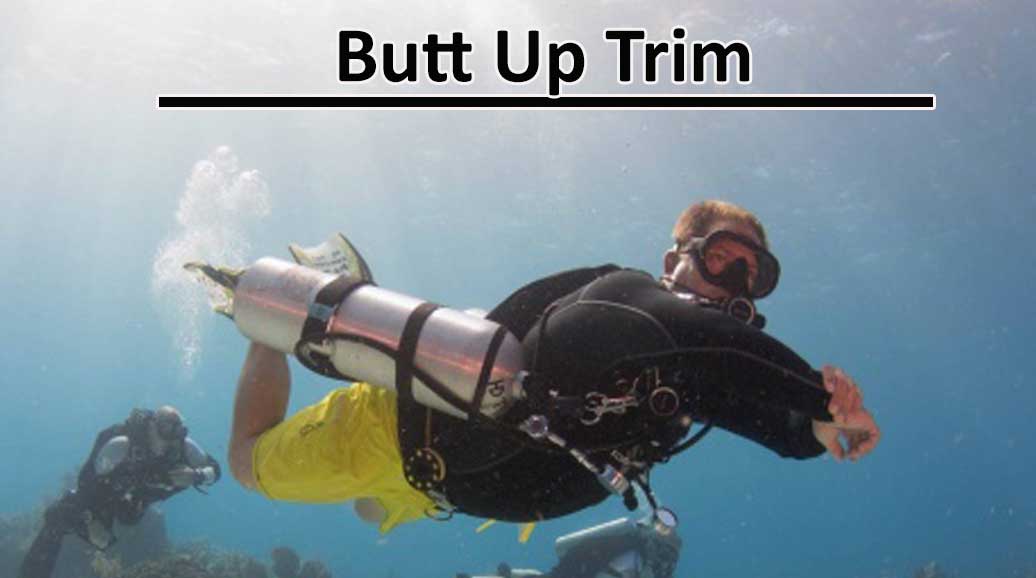

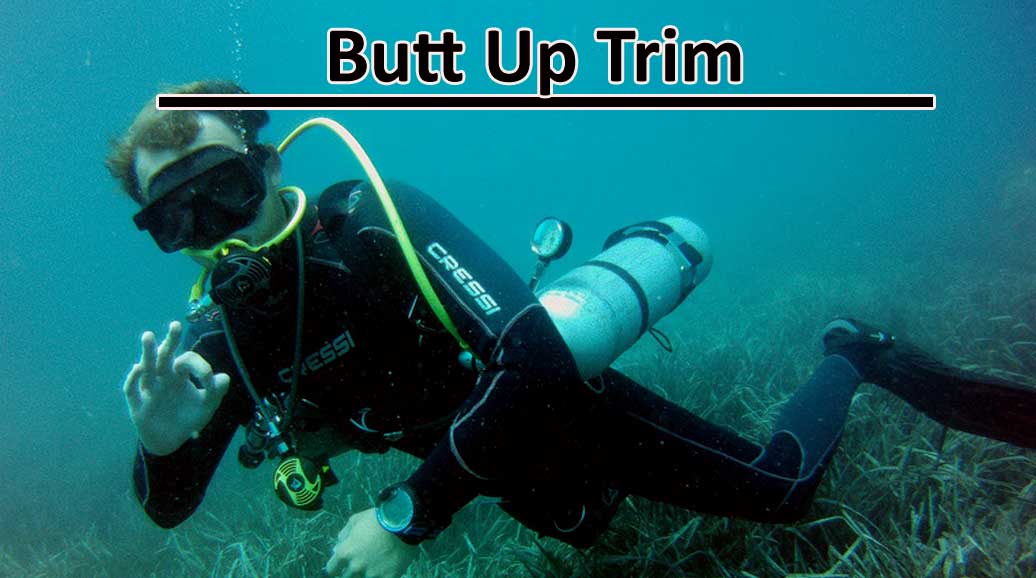

Butt Up Cylinder Trim

‘Butt up trim’ differs from ‘valve down trim’ because, you guessed it, the valve doesn’t drop below the diver.

In this instance the bungees are sized and configured correctly; and the issue lies solely with the lower cylinder attachment.

There are a number of factors that can be wrong about the lower cylinder attachment point. The most glaring issue is normally when sidemount divers try to use aluminium cylinders with butt-plates designed for steel cylinders.

You need a much longer leash/bolt-snap to reach from the band to the butt-plate. That’s not an issue with steel cylinders that will forever conveniently hang down negatively buoyant – sidemount cylinder trim is much easier with steel tanks.

But for aluminium cylinders, when they get floaty that long leash/bolt-snap gives far too much range of motion for the tank base to rise upwards.

Even if using D-rings on the waistband, if they’re setup in less than optimum position, or your leash/bolt-snap is too long, then it can still lead to ‘butt up trim’. The sidemount diver (above) is demonstrating an issue with floaty aluminium cylinders.

He’s either forgotten to shift them to the front waist D-rings, or he’s trying to attach them via a butt-plate. The result is far from streamlined and also degrades stability and comfort. In overhead environments, it can easily mean you’re prone to smashing the bejeezus out of the ceiling… causing a major hazard to yourself and others.

There’s a whole long list of what’s less than optimal about the above diver’s configuration. He really shouldn’t be making the “OK” sign, as things are obviously far from okay…

We can see that his cylinders are more than 45 degrees raised above his torso centreline. This is probably due to using a buttplate with aluminium cylinders and also by having a very long leash/bolt-snap to attach them. His valves are also quite low below his armpits. The pivot effect on his cylinder is very obvious.

Given that he’s set up his rig for attaching to a buttplate, he doesn’t have many options to shift the lower attachment to a front D-ring. Look at where his cylinder band is. If he shifted to a front attachment then he’d only be shifting his problem from ‘butt up trim’ to a drastic ‘tank forwards trim’. Which would be the lesser of the two evils?

Don’t use butt-plate sidemount BCDs with aluminium cylinder folks… it’s not the route to success with sidemount cylinder trim.

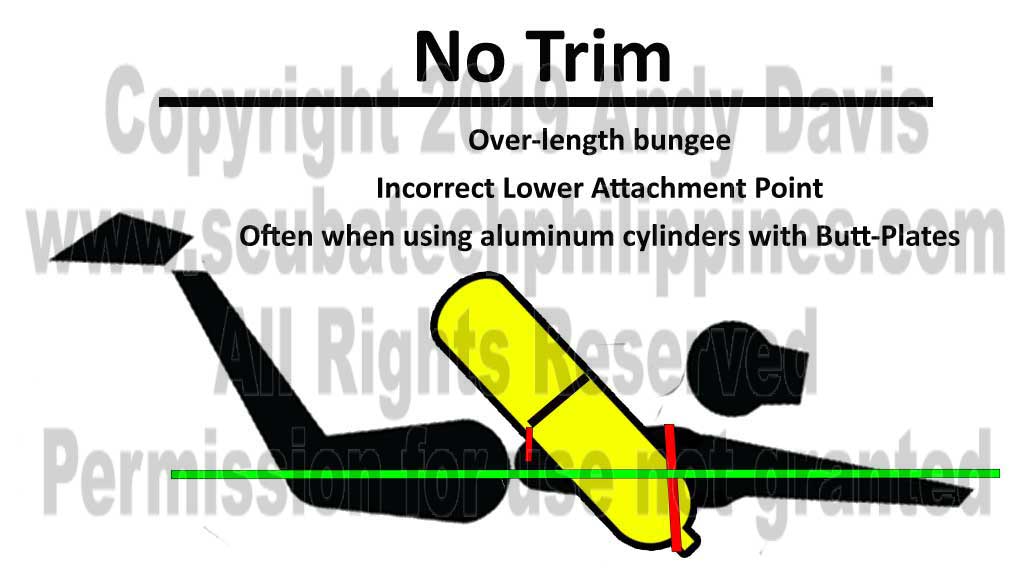

No Sidemount Cylinder Trim

Here we have the true “master of disaster” – ‘no trim’ whatsoever; a configuration where both cylinder attachment points are woefully setup. The valve drops below and the cylinder bottom rises proudly aloft. In this case, the cylinder is more vertical than horizontal.

It’s a dreadful experience in the water. You’d feel very ungainly and unstable. It’d stretch and tug your regulator hoses as the valve dropped lower… and the cylinder would “wobble” annoyingly whenever you tried to manoeuvre yourself around.

The example above is pretty classic. I would assume that the diver had received zero sidemount training. The cylinders are on their merry way towards being at 90 degrees to the divers trim position.

The solution is to tighten the bungees significantly. Then reconfigure the lower attachment points. These cylinders need a much shorter lower leash/bolt-snap; and they need to be clipped onto waist D-rings at the front of the diver’s hips.

Cold-water divers who predominantly use steel cylinders do have problems adjusting their configuration for the use of aluminum tanks. The first step is to understand that an entirely different set of configuration principles need to be applied.

The diver (above right) is using aluminum cylinders with a steel cylinder approach. The tank valve is much lower than the armpit and the base of the cylinder is barely restrained from rising – again, because it’s been clipped onto a butt-plate/rail attachment.

The diver’s “lollipop” SPGs are now pointing down at the floor and would constitute a severe entanglement hazard in wrecks or caves where guidelines are used. The cylinders are also liable to crash, clang and wallop on the ceiling in confined areas.

Another example of ‘no trim’. We can plainly see that the diver has front waist D-rings, but has perhaps forgotten to shift his aluminium cylinders down to that lower attachment position once the cylinders became buoyant.

It pays dividends to pay attention to your cylinders behaviour on a couple of dives. Most aluminium cylinders become tail buoyant at around 1800-2200psi (120-160 bar), depending on the brand and also the weight of the valves and regulator 1st stages used. If you are swapping regulators every 500psi/35 bar, then you should definitely be checking your tank trim on those first and second reg switches.

Nonetheless, the example above isn’t just about not moving the lower attachment point; as the valve is hanging down at least 12″ below the armpit; which indicates that the bungees are also much too loose.

This last example of ‘no trim’ illustrates that, even when switching the aluminium cylinder to a front waist D-ring attachment, the tank tail can still rise up.

Again, the cylinder valve is a full 12″ below the armpit, so those bungees need to be tightened considerably. The lower attachment, whilst correctly moved forwards, is still insufficient in arresting the rise of the cylinder.

In this case, I suspect that the diver has an overly long bolt-snap and leash – which are giving the tank too much freedom to move/rise. The front waist D-ring also needs to be moved much further forwards on the waist belt; over the hips, not just an inch or two beyond the torso centreline.

When it comes to sidemount cylinder trim, every inch is critical. That’s true for both the bungees and the components/locations used for the lower cylinder attachment.

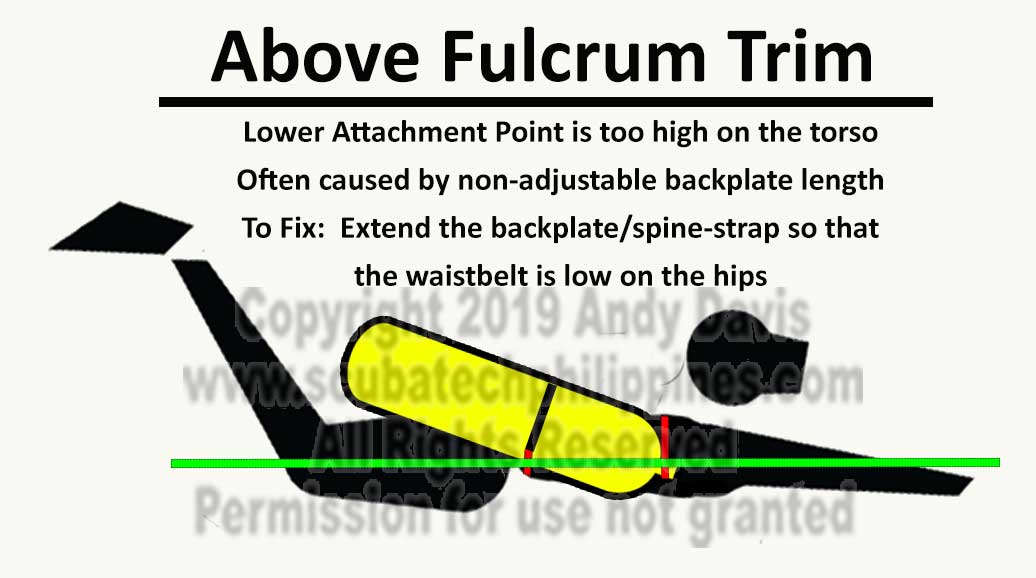

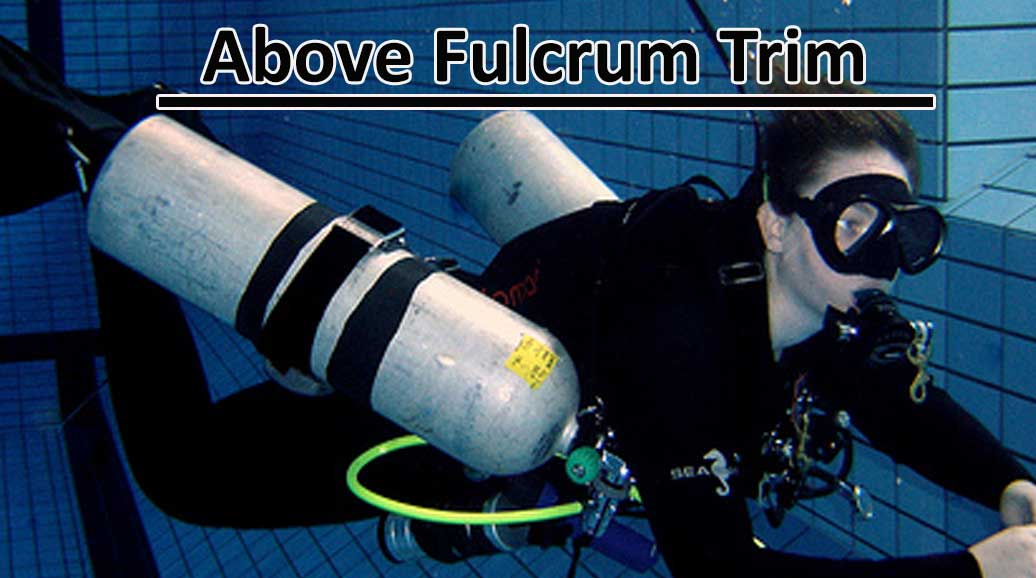

Above Fulcrum Trim

The last major sidemount cylinder trim catastrophe is the ‘above fulcrum trim’. This is where the sidemount diver has setup their cylinder bands too high on the tanks. Cylinders have a fulcrum or balance point, and the band must be below this point if it is to have any effect in keeping the tail of the tank down.

That fulcrum varies with the cylinder brand and the weight of the valves and regulator 1st stages used. Needless to say, it also shifts upwards as gas is consumed from the cylinder.

This is a particular problem for sidemount divers of very short height. I’ve encountered this problem on numerous occasions when teaching sidemount to very petite SE Asian girls.

The distance between their armpits and their hips is very short – but this distance needs to correspond the distance from valve to band on the cylinder.

See here for an explanation: How to find the Optimal Height for Sidemount Tank Bands.

In these cases, every millimetre counts – we have to lengthen the spine strap and get the waist belt really, really low on the hips.

One of the biggest barriers to getting the waistband where it’s needed are those sidemount BCDs that use a backplate system (hard or soft), rather than a shoulder-lumbar plate system connected via spine webbing. The problem with backplates is that you can’t adjust for torso length.

This was the closest example I could find online to illustrate ‘above fulcrum trim’, although there’s also other issues at play – like the bungees being too long. You can see that the diver pictured above has, out of desperation, attached to hulking lead weights to their cylinder in a forlorn attempt at making the cylinders behave.

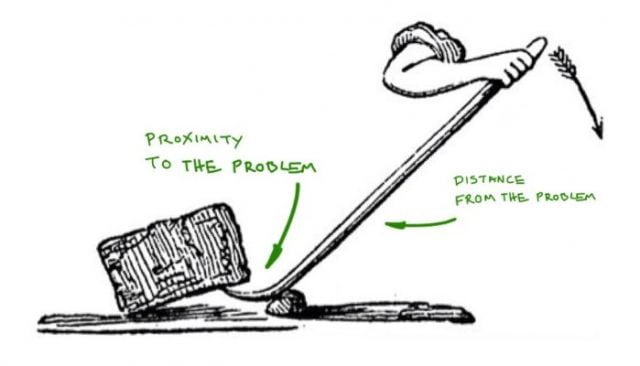

But given an understanding of levers and fulcrums, we can see that the weights… and the attachment points… are really close in at the balance point. They’re really having no effect whatsoever.

They certainly aren’t going to offset the weight of the cylinder valve and regulator 1st stage; which aren’t as heavy, but ARE much further out at the end of the cylinder and winning the battle of gravity due to the lever effect.

A reminder of the forces at play;

The diver above really needs to lower their cylinder band somewhat. But to do that they’d need to also lower their attachment position. They either aren’t using a BCD that allows such adjustment (a soft or hard backplate), or they’ve not correctly setup their BCD to get the waist belt low down on the hips.

All it would really take is some adjustment to the BCD setup and to shorten the bungees by maybe 6″. There really isn’t any need (or benefit) to having the weights on their cylinder bands at all. That’s not how you manage sidemount cylinder trim with aluminum cylinders.

If you’re having problems with your own sidemount cylinder trim, please do drop me a line – I’m happy to help. Video or photos do help a diagnosis.

Authors note: Many of the photographic images used in this article were shared on public Facebook groups and internet discussion forums. My purpose in using them is entirely educational, for the public benefit, and intends to comply with ‘Fair Use’ provisions to copyright regulation. If the owners of any of these photos desire attribution, please simply contact me and ask.

Read more of my sidemount diving articles!

About The Author

Andy Davis is a RAID, PADI TecRec, ANDI, BSAC, and SSI-qualified independent technical diving instructor who specializes in teaching sidemount, trimix, and advanced wreck diving courses.

Currently residing in Subic Bay, Philippines; he has amassed more than 10,000 open-circuit and CCR dives over three decades of challenging diving across the globe.

Andy has published numerous diving magazine articles and designed advanced certification courses for several dive training agencies, He regularly tests and reviews new dive gear for scuba equipment manufacturers. Andy is currently writing a series of advanced diving books and creating a range of tech diving clothing and accessories.

Prior to becoming a professional technical diving educator in 2006, Andy was a commissioned officer in the Royal Air Force and has served in Iraq, Afghanistan, Belize, and Cyprus.

In 2023, Andy was named in the “Who’s Who of Sidemount” list by GUE InDepth Magazine.

Purchase my exclusive diving ebooks!

Originally posted 2018-03-07 23:56:21.

Sure Ben, drop me a line via the contact form or via Facebook Messenger

Hey Andy,

Great article, would you mind helping out and advice on what is the best approach for trimming the tanks ?

I would like to share with you some video my dive buddy took while we are diving.

Thank you and regards,

Benjamin